You might remember Dell's Concept Luna, which was Dell's vision for a future fully sustainable and repairable PC. A year after its announcement, the company is taking it to the next level. While still not an official product yet, Dell has now refined the modular aspect of Concept Luna, showing the possibilities of making the laptop disassembly and repair process faster and more efficient.

To speed up that process, Dell's Experience Innovation Group engineers tweaked the design of Project Luna to minimize the use of adhesives, cables, and screws. The company mentioned that with existing technology and these components, it can take partners more and an hour to disassemble a PC. The new Concept Luna design brings the timing of that process down to just minutes.

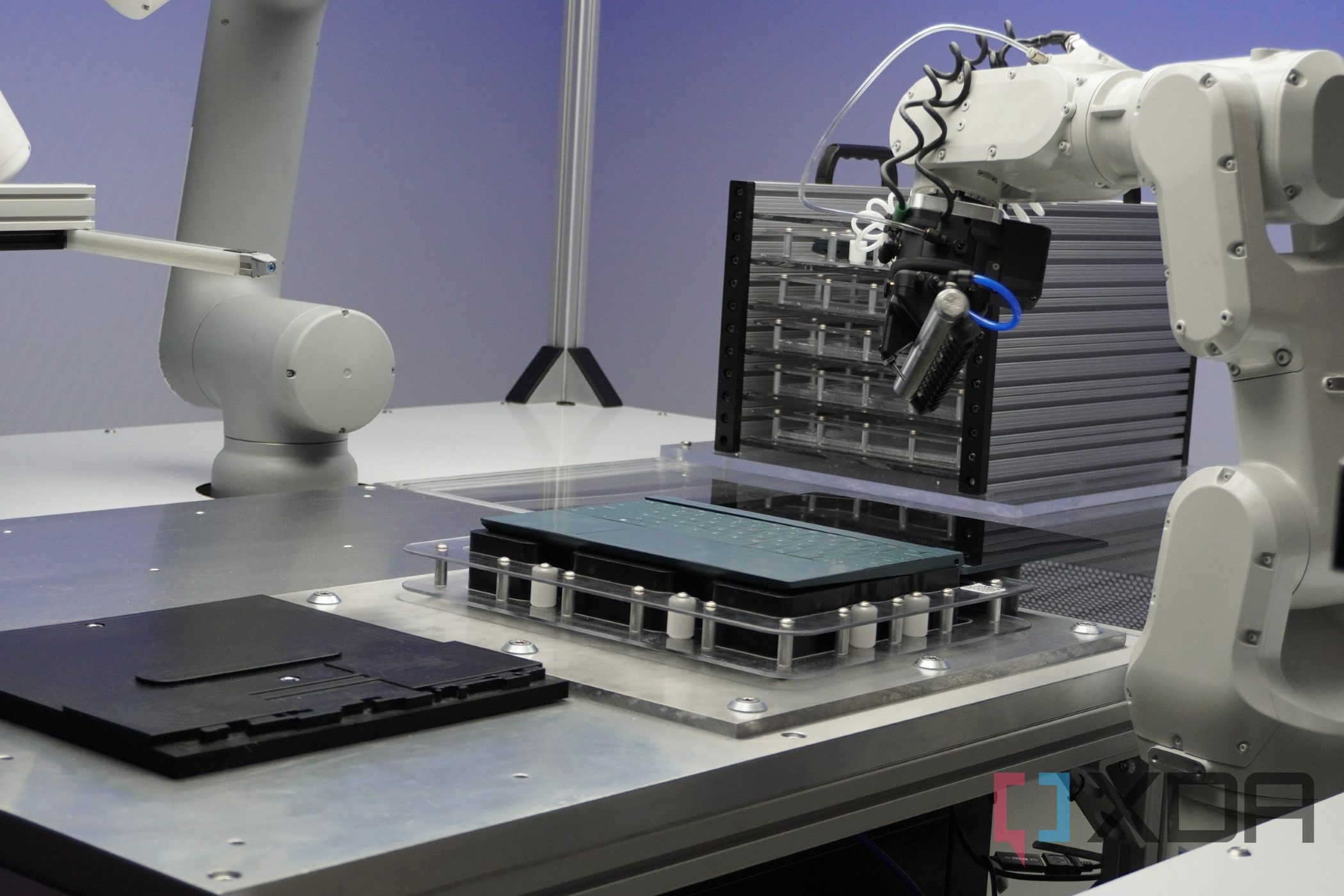

At the same time, this means that the components of Luna will be more accessible and reusable. During a press event in New York, Dell showcased a micro-factory that can guide design teams. The micro-factory uses robots that can quickly and easily take the Concept Luna laptop apart, with the use of suction cups. There is even telemetry built into Luna that can diagnose the health of a system and its components, to reduce the need to waste parts like the keyboard or monitor when replacing a motherboard.

Dell's long-term idea is that this can trigger a shift in the laptop industry to create millions of more sustainable tech devices, while also optimizing the materials in those devices for future use and even recycling. It is all part of the company's sustainability goals, as well as circular design practices.

As a company, Dell hopes that by 2030, 100% of its packaging will be made of recycled or renewable materials, and more than half of its product content will be made from recycled or renewable materials. The company has already used more than 396.5 million pounds of sustainable materials in its packing and products.